Akfen Engineering carries out domestic and international turnkey projects for the installation of mineral oil facilities. Let your project take place among the successful projects of Akfen Machine, offering high quality and price guarantee turnkey projects for the installation, assembly, design, electrical installation, piping workmanship, personnel training, automation, insulation, performance tests and commissioning of the mineral oil plant for the desired capacity (In Europe, Arab Countries, Africa) in European countries.

Let your project take place among the successful projects of Akfen Machine, offering quality products and affordable price guarantee.

One of the raw materials obtained as a result of the refining of crude oil is mineral oils. A second refining process is carried out in order to separate the mineral oils according to their densities. After the second refining process, crude base oils such as SN80, SN150, SN 350 and SN500 are obtained.

Duties of Mineral Oils

Mineral oils enable the parts to move easily by reducing friction between surfaces.

Mineral oils are obtained by mixing base oils of different intensities with various additives selected according to the features expected from resulting product.

Industrial Oils;

Heat treatment oils, Metal Processing Oils, Leather and Textile processing oils, Hydraulic oils, transmission oils, skid oils, rust-preventive and rust-solvent preparations oil, full synthetic industrial oils, etc.

Automotive Oils;

Lubricating oils, gear oils, roller bearing and bearing oils, transmission oils, machine oils, greases, synthetic oils, etc.

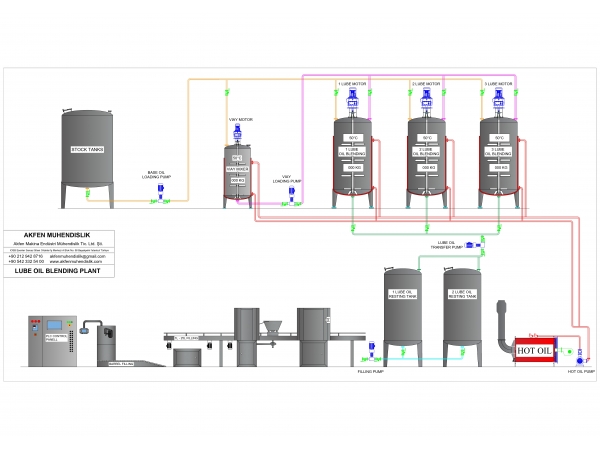

Mineral Oil Production Plantsand System Operation Principles;

The base oil suitable for production is sent to the production mixer according to the type of mineral oil to be produced.

The formulation prepared in Vijay and additive mixers is mixed under heat by being added to the base oil in the production mixer. After a certain period of time, sample products are taken for the laboratory, the mineral oil production is completed after the necessary checks are completed.

Equipment to Be Found in The Mineral Oil Production Plant;

- Raw Material Tanks

- End Product Tanks

- Production Mixers

- Plant Process and Automation Procedures

- Stock Field

- Automatic or semi-automatic filling machines

- Circulation and pressing pumps

- Laboratory and testers

- Weighbridges and scales

Our company offers turnkey solutions in the installation of mineral oil plant, mineral oil plant, installation of mineral oil factory, mineral oil production plant, installation of lubricating oil plant and installation of lubricating oil blending plant.

|

MODELS |

AK-MY 5 |

AK-MY 20 |

AK-MY 50 |

AK-MY 100 |

AK |

|

|

Daily Processing Capacity |

5.000 |

20.000 |

50.000 |

100.000 |

|

|

|

Total processing time |

8 Hours |

8 Hours |

8 Hours |

8 Hours |

||

|

Required factory field |

200 m2 |

500 m2 |

600 m2 |

800 m2 |

||

|

Products to Be Produced |

Hot Oil Boiler, Steam Boiler or Electric Resistance |

|||||

|

Raw materials |

Automotive Oils (Diesel and Gasoline Oils) Industrial Oils (Gear Oil, Cutting Oil, Machine Oil) |

|||||

|

Operation System |

SN-80 , SN-150 , SN-300, SN-500 Base Oil And Recycling Base Oil |

|||||

|

Lab |

Diesel, Fuel Oil, Gas and Electricity |

|||||

|

Heating Type |

Loadcell Automation System or Semi-Automatic Manual System |

|||||

|

Heating Fuel |

Standard Basic Laboratory Equipments are Required for System Operation |

|||||

|

Necessary Manpower |

1 Senior Engineer 1 Personnel |

1 Senior Engineer 3 Personnel |

2 Senior Engineer 5 Personnel |

2 Senior Engineer 7 Personnel |

||

|

Delivery time |

30 Workdays |

35 Workdays |

45 Workdays |

60 Workdays |

||

|

Assembly time |

5 Workdays |

10 Workdays |

15 Workdays |

20 Workdays |

||